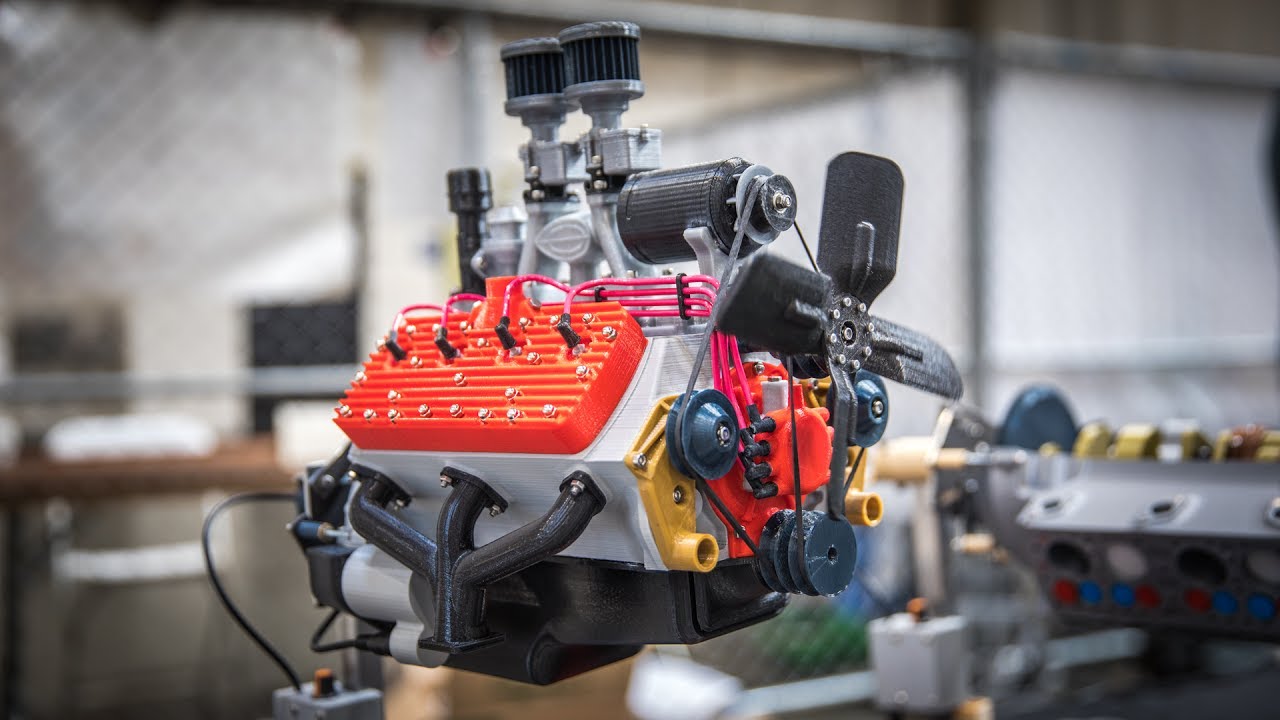

3d Printed Car Engine Model

3D Printed Car Engine Model

3D printing is rapidly gaining ground as a viable and cost-effective way to make models for any kind of engine, including car engines. It is becoming a popular choice for hobbyists, engineering students, and automotive enthusiasts alike. With a 3D printed car engine model, you can get a detailed and accurate representation of the real thing without having to build it from scratch. In this article, we'll explain how 3D printing works and how you can use it to create your own car engine model.

What is 3D Printing?

3D printing is a manufacturing process whereby a three-dimensional object is created by laying down successive layers of material. 3D printers essentially work like regular inkjet printers, but instead of printing on paper they print onto a plastic, metal, or other material. The printer builds up the object layer by layer, creating the desired shape. This is a much faster and more precise way of creating objects than traditional manufacturing methods.

Benefits of 3D Printing

One of the primary benefits of 3D printing is that it allows for the creation of objects that are very complex and detailed. This makes it ideal for creating car engine models since the intricate parts can be accurately replicated. Additionally, 3D printing is faster and cheaper than traditional manufacturing methods, making it a cost-effective option for hobbyists and automotive enthusiasts. The materials used to 3D print objects are also much stronger and more durable than those used in traditional manufacturing.

Creating a 3D Printed Car Engine Model

The process of creating a 3D printed car engine model is relatively straightforward. First, you'll need to create a 3D model of the engine using a 3D modeling software such as Autodesk Fusion 360 or Solidworks. Once the model is complete, you can then upload it to a 3D printing service, such as Shapeways or Sculpteo, which will then print the model using a variety of materials. The finished product will be a detailed and accurate representation of the actual engine.

Advantages of 3D Printed Car Engine Models

3D printed car engine models offer a number of advantages over traditional models. They are much more detailed and accurate, making them ideal for engineering students or hobbyists who want to get a better understanding of how car engines work. Additionally, 3D printed models are much stronger and more durable than traditional models, meaning they will last much longer. Finally, 3D printing is much faster and more cost-effective than traditional manufacturing methods, making it a great option for those looking to create their own car engine model.

Conclusion

3D printed car engine models are an excellent way to get a detailed and accurate representation of the actual engine without having to build it from scratch. They are much faster and more cost-effective than traditional manufacturing methods, making them a great option for hobbyists and automotive enthusiasts alike. Additionally, they are much stronger and more durable than traditional models, making them ideal for engineering students who want to get an in-depth understanding of how car engines work. With a 3D printed car engine model, you can get an accurate and detailed representation of the real thing.