3d Cad Models For 3d Printing

3D Cad Models For 3D Printing

Introduction

3D printing has been making waves in the manufacturing industry for years now. It has been used for a variety of applications, from prototyping to creating custom parts and products. With the advent of 3D printing, new possibilities for creating custom objects have become available to everyone.

3D printing works by layering thin layers of a material, such as plastic or metal, to create a 3D object. This object is created from a 3D computer-aided design (CAD) model. CAD models are digital 3D representations of physical objects, and they can be used to create 3D prints.

In this tutorial, we will discuss 3D CAD models and how they are used for 3D printing.

What is a 3D CAD Model?

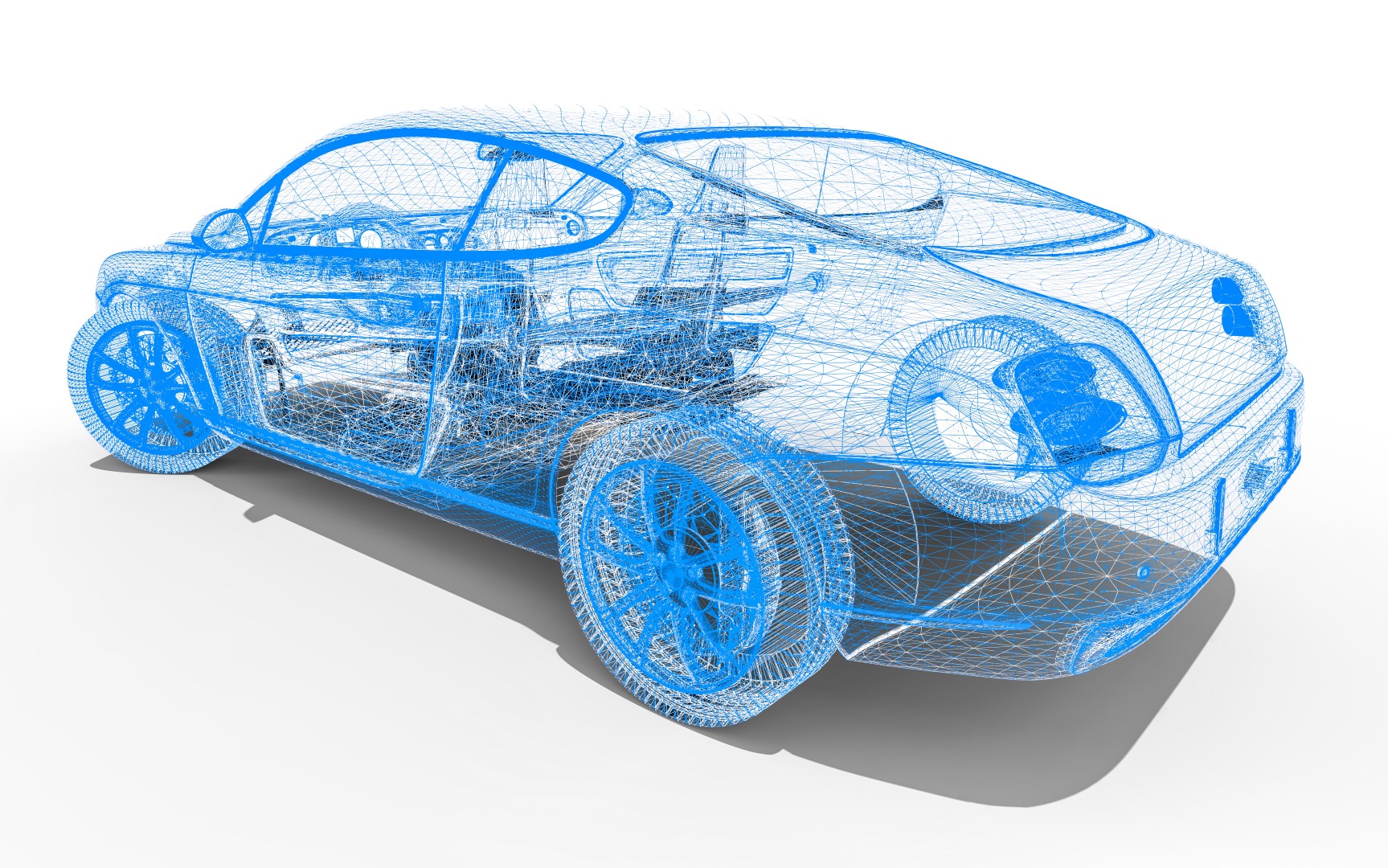

A 3D CAD model is a digital representation of a physical object. It is created using a 3D modeling software such as Autodesk Fusion 360, Sketchup, or Blender. A 3D CAD model consists of a collection of points (vertices) in 3D space, connected by line segments (edges), and faces that form the surface of the object.

The 3D CAD model can then be used to create a 3D print. The 3D print can be of any material, such as plastic, metal, or even ceramic. The 3D printer uses the CAD model to create the object layer by layer, creating a physical object from the digital representation.

Advantages of 3D CAD Models

3D CAD models offer a number of advantages over traditional manufacturing methods. For one, they are much faster and cheaper to create than traditional methods. 3D CAD models can also be used to create complex shapes and objects that would be difficult or impossible to create using traditional methods.

Another advantage of 3D CAD models is that they can be used to create prototypes quickly and easily. This can be useful for testing and verifying designs before committing to large-scale manufacturing. 3D CAD models can also be used to create custom parts and products, which can be useful for a variety of applications.

Creating a 3D CAD Model

Creating a 3D CAD model requires knowledge of 3D modeling software and techniques. Most 3D modeling software has a steep learning curve, so it is important to learn the basics before attempting to create a 3D CAD model.

Once the basics of 3D modeling have been mastered, the process of creating a 3D CAD model is relatively straightforward. The modeler begins by creating a 3D wireframe of the object, which is then refined and smoothed out. The model is then textured and colored to give it a realistic look and feel.

Using a 3D CAD Model for 3D Printing

Once the 3D CAD model has been created, it can be used to create a 3D print. The 3D print can be of any material, such as plastic, metal, or ceramic. The 3D printer uses the 3D CAD model to create the object layer by layer, creating a physical object from the digital representation.

The 3D printer then prints the object layer by layer, following the instructions from the 3D CAD model. Once the 3D print has been completed, it can be used for a variety of applications, such as prototyping, custom parts, or even creating art.

Conclusion

3D CAD models are digital representations of physical objects that can be used to create 3D prints. They offer a number of advantages over traditional manufacturing methods, including speed, cost, and the ability to create complex shapes and objects. 3D CAD models can be used to create prototypes quickly and easily, as well as custom parts and products.

Creating a 3D CAD model requires knowledge of 3D modeling software and techniques. Once the 3D CAD model has been created, it can be used to create a 3D print using a 3D printer. The 3D print can then be used for a variety of applications, such as prototyping, custom parts, or even creating art.