Raspberry Pi 2 3d Model

Building a 3D Model with Raspberry Pi 2

Introduction

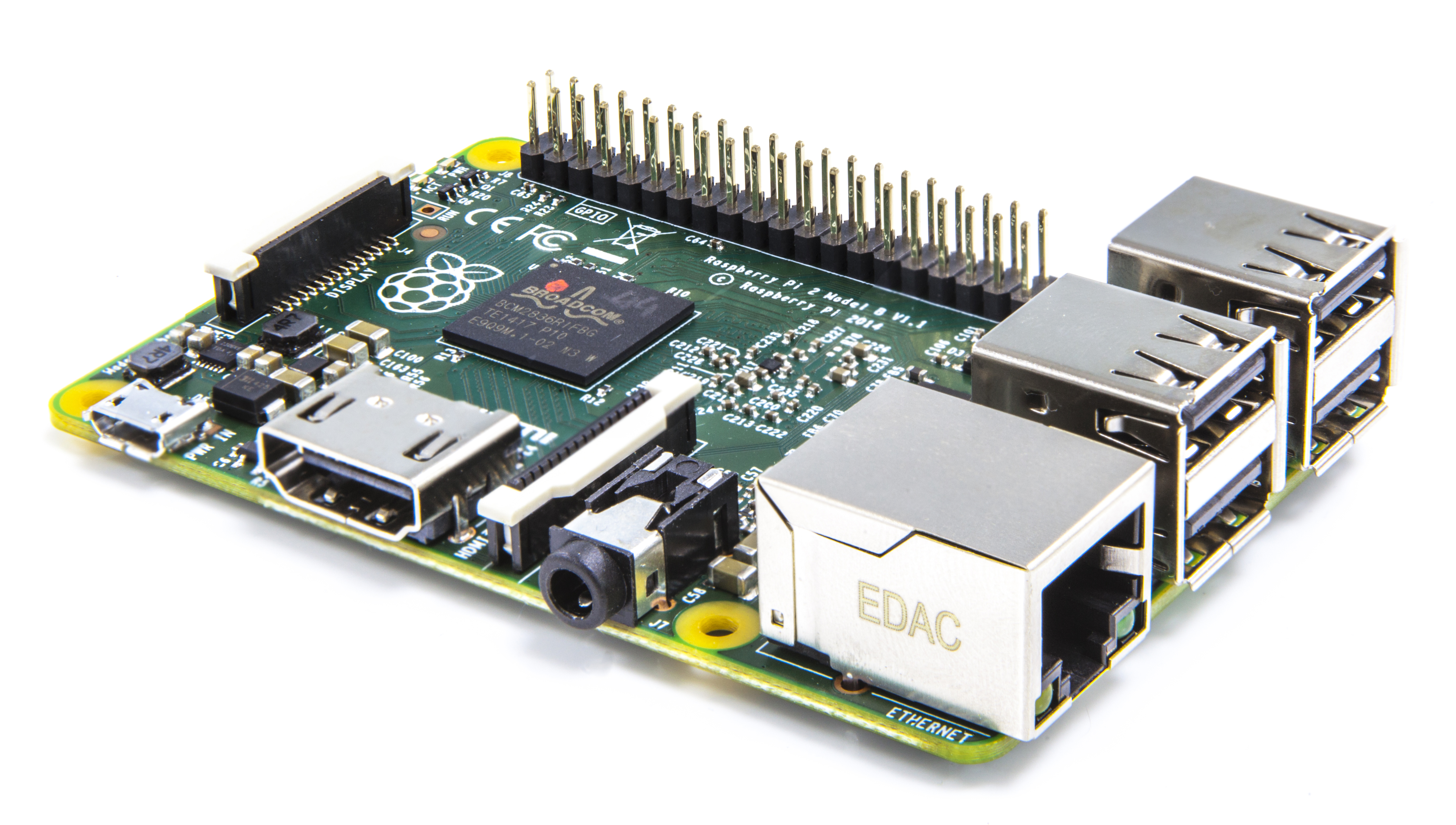

The Raspberry Pi 2 is a powerful, low-cost, and compact single-board computer that is used by makers around the world. It can be used in a variety of projects, from basic electronics projects to robotics projects. One of the most popular uses for the Raspberry Pi 2 is to use it to build 3D models. In this tutorial, we’ll show you how to build a 3D model using the Raspberry Pi 2.

What You’ll Need

To build a 3D model using the Raspberry Pi 2, you’ll need the following items: the Raspberry Pi 2, a microSD card, a 3D printer, 3D printing filament, a 3D printing software package, and a 3D design software package.

Step 1: Set Up the Raspberry Pi 2

The first step is to set up the Raspberry Pi 2. To do this, you’ll need to install the operating system on the microSD card. The Raspberry Pi 2 comes with a version of the Raspbian operating system pre-installed, but you can also download and install a different operating system, such as Ubuntu or Windows 10 IoT Core. Once you’ve installed the operating system, you’ll need to connect the Raspberry Pi 2 to a monitor, keyboard, and mouse.

Step 2: Install the 3D Printing Software

Once you’ve set up the Raspberry Pi 2, you’ll need to install the 3D printing software. This software will allow you to control the 3D printer and print the 3D model. There are several 3D printing software packages available, including Cura, Repetier, and OctoPrint. The software package you choose will depend on your particular 3D printer.

Step 3: Design the 3D Model

The next step is to design the 3D model. There are several 3D design software packages available, including Blender, SketchUp, and AutoCAD. The software package you choose will depend on the type of model you’re trying to create. Once you’ve designed the 3D model, you’ll need to export it as an .stl file, which is the file type used for 3D printing.

Step 4: Print the 3D Model

Once you’ve designed the 3D model, you can use the 3D printing software to print the model. You’ll need to select the correct settings for the 3D printer, such as the layer height and the printing speed. Once you’ve selected the correct settings, you can start the printing process. Depending on the size of the model, the printing process can take several hours.

Step 5: Post-Processing the 3D Model

Once the 3D model is printed, you’ll need to do some post-processing. This involves removing the supports and other parts of the model that are not needed. You can use a pair of pliers, a file, or a hobby knife to remove the supports. Once the supports are removed, you can sand and polish the model to give it a smooth finish.